The top 4 services of rapid prototyping

Many manufacturers do their best to undertake and keep being at the highest of their product when it involves rapid prototyping. Bright Prototypes isn’t the exception. The marketplace for manufacturing industries & 3d printing is wide open since the planet is the playground for each entrepreneur willing to dip their toes during this field, even small-scale operators within the mainland. There’s a manufacturer who has just what you would like regarding prices, technology, and logistics. Even so, not most are capable of providing excellent service, not every company can add the time frames required from their customers. It doesn’t have anything to do with willingness, more often, than it’s to try to do with the manufacturer’s actual capabilities to supply the services they advertise. When a corporation is bent on producing manufactured goods, it must intensify their game and invest some money within the latest developments necessary to make rapid prototypes and handle production cycles with precision and assertiveness. That’s the reason we have the best CNC machining and custom CNC machining services. All of our CNC machines are advance machine, and we have the capability of manufacturing your desired product without the slightest flaw.

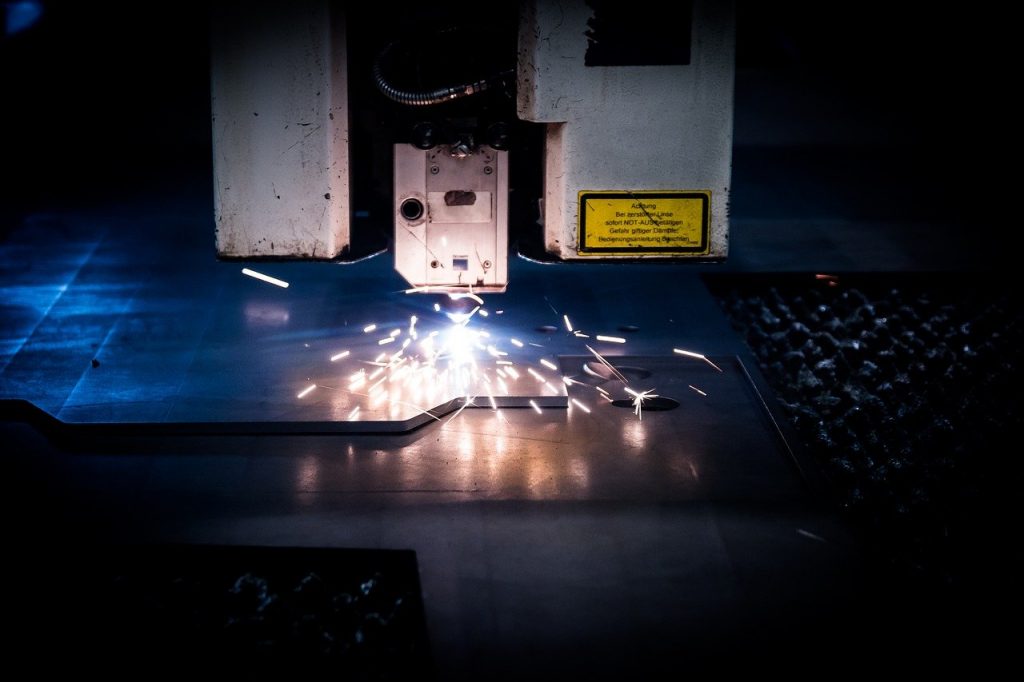

Unlike additive manufacturing techniques like 3D printing, CNC machining may be a subtraction process. This involves trimming or cutting away at a base material to a particular specification.

CNC machining is especially important in metal and plastic manufacturing processes, CNC machining holds several advantages over alternative manufacturing processes, like lower labor costs. One of the key advantages of CNC machining is that it can reduce a company’s labor costs, precision, Increased productivity, repetition, Speed up prototyping, design complexity and much more. We provide sheet metal fabrication metal cutting and bending services for the fabrication of sheet metal parts. High precision and quality of ready parts is guaranteed by the automated cutting processes. All parts are often subject to post-processing upon your request: coatings, heat-treatment et al.

Vacuum casting may be a tried and tested process for producing multiple high-quality models and prototypes for a full scope of applications; including form, fit, and performance testing. We’ve the simplest vacuum casting that you simply can get. Forward-thinking and well-equipped, we pride oneself within the quality of labor we produce. We concentrate on detail and communicate with our customers, so we will deliver what our customers ask folks. So not only can we offer everything our customers need in one place, we will also offer quick turnaround times at competitive prices.

Call us with your project or requirement on +86 13692141599 or email us on [email protected]