The seven benefits of 3D printing

People from various industries with different backgrounds and professional skills are described in a similar way. 3D printing helps them reduce major cost, time and complexity barriers.

Reduce production costs

Manufacturing complex items does not increase the cost. As traditional manufacturing, the more complex the shape of the object, the higher the manufacturing cost. but for 3D printing, the cost of manufacturing objects with complex shapes does not increase, and manufacturing a gorgeous object with complex shapes does not take more time, cost, skill. Manufacturing complex items without increasing costs will break the traditional pricing model and change the way we calculate manufacturing costs.

Product diversification

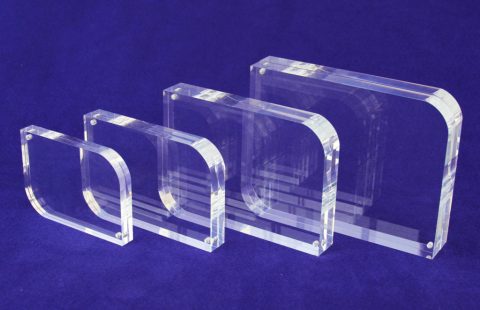

Product diversification does not increase costs. A 3D printer can print many shapes, and it can make objects of different shapes every time like a craftsman. Traditional manufacturing equipment has fewer functions and limited types of shapes. 3D printing saves the cost of training mechanics or purchasing new equipment. A 3D printer only needs different digital design blueprints and a batch of new raw materials.

No assembly required

3D printing can make parts integrated. Traditional mass production is based on assembly lines. In modern factories, machines produce the same parts, which assembled by robots or workers (even across continents). The more product components, the more time and cost it takes to assemble. But the 3D printer can print a door and its matching hinges at the same time through layered manufacturing, without assembly. no assembly so that shortens the supply chain, saving labor and transportation costs, and shorten the supply chain, the less pollution as well.

Zero delivery time

The 3D printing can print on demand. Instant production reduces the company’s physical inventory, and companies can use 3D printers to create special or customized products to meet customer needs based on customer orders, so new business models will become possible. If the goods people need are produced nearby on demand, zero-time delivery production can minimize the cost of long-distance transportation.

Infinite design space

Traditional manufacturing techniques and artisans have limited product shapes, and the ability to make shapes is limited by the tools used. For example, traditional wooden lathes can only produce round objects, rolling mills can only process parts assembled with milling cutters, and mold making machines can only produce molded shapes. 3D printers can break through these limitations, open up a huge design space, and even make shapes that may only exist in nature.

Zero skill manufacturing

Traditional craftsmen need to be apprentices for several years to master the required skills. Mass production and computer-controlled manufacturing machines reduce the requirements for skills, but traditional manufacturing machines still require skilled professionals for machine adjustment and calibration. 3D printers obtain various instructions from the design documents to make the same complex items. 3D printers require fewer operating skills than injection molding machines. Unskilled manufacturing has opened up new business models and can provide people with new production methods in remote environments or extreme situations.

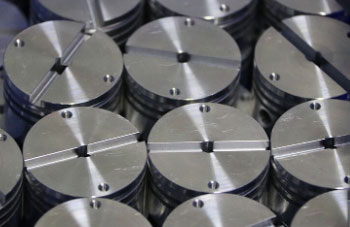

Reduce waste with additive manufacturing

Compared with traditional metal manufacturing technology, 3D printing waste fewer materials. 90% of the metal raw materials are discarded in the factory floor. 3D printing reduces the amount of waste when manufacturing metal. With the advancement of printing materials, “net shape” manufacturing may become a more environmentally friendly processing method.

3D printing gives you the latest innovations. Additive Manufacturing is growing like no other industry. It allows you to improve your proof of concept by providing you with new, faster solutions to produce it, a variety of materials and technologies to choose from and cutting-edge 3D design solutions. Don’t waste any more time and start using 3D printing for your proof of concept right now!

If you consider 3D printing technologies for your proof of concept or any other project, feel free to contact us. We’re here to help you develop your idea, pick the right material or technology. And if you already made up your mind, go ahead and send your 3D model to our email.