Vacuum Casting

- Home

- Service

- Vacuum Casting

- Vacuum Casting

Vacuum Casting

What’s Vacuum Casting?

Vacuum casting is a casting process for duplicating plastic products, using 3D printing and CNC machining to create the master patterns for silicone and urethane mold-making, then it is poured by liquid urethane material and made silicone mold in vacuum state, so that replicate prototypes and end user parts.

If the product still at the early stage of development, then the vacuum casting is the best solution. it is different from Injection modeling, it just needs spend few days to make a mould, it a fast way to produce small batch production in low cost, greatly reducing the cost, cycle and risk of product development, helping you make product to market faster than the competitions.

Advantage of Vacuum Casting

- No requirement for expensive and slow-paced hard tooling, mould can be made in few days in low cost.

- Colorful plastic material options, and the resinliquid with color is mixed into the silicone mould. color not easy to scratch.

- Wide range of materials and surface finishes, it can be made the parts your unique needs.

- Fine detail and accuracy,high-quality finishes with the look and feel of final products.

- Perfect for functional testing or marketing, and low volume production runs. bridges the gap between injection moldin.

The Process of Vacuum Casting

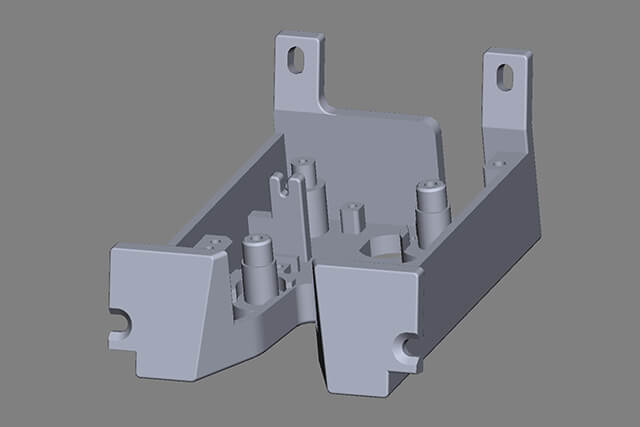

Create Master Pattern

Using 3D printing or CNC Machining to create the master pattern for silicone molding, as well as the real sample.

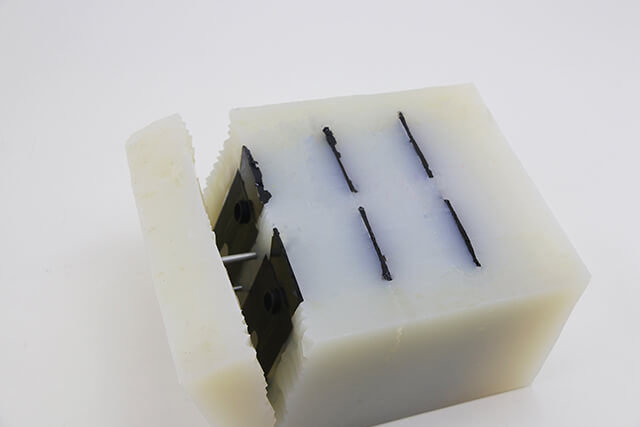

Make Silicone Mould

The pattern is encased in quick-curing liquid silicone to form a cavity within the mold, After the mould cures, it is cut in half and the pattern is removed. The cavity formed by the master pattern is used for casting the end product.

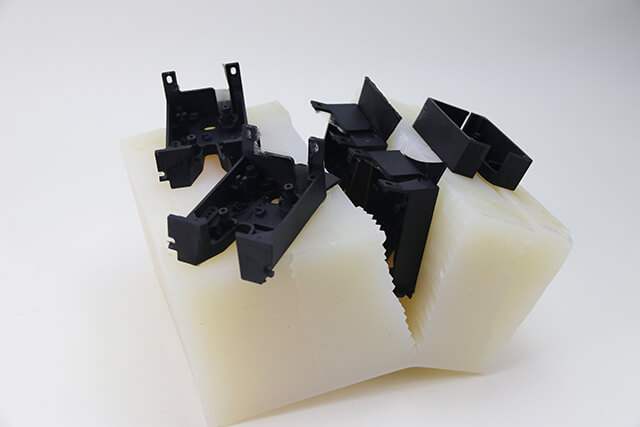

Injecting the resin

Put the silicone mould into the vacuum casting machine, the mixed resin is injected to the empty cavity of mould.

Copies Removal

Once the resin dried, remove the copy from the mould, then the part has finished. the mould are durable for approximately 20 copies.

Vacuum Casting Materials

- ABS

- POM

- Acrylic

- Elastomers (transparent & opaque, range: 25 – 95 Shore A)

- Nylon including glass filled

- Polypropylene

Vacuum Casting Technical Details