10 common materials used in CNC machining

Compared with 3D printing, the biggest advantage of CNC machining is the richness and practicability of the material. The main purpose of the prototype is to verify the feasibility of product design, so the material of the prototype is also very particular. The products of each company are different, and the prototype to be produced is different. Therefore, the materials may be different, but the main processing materials include the following:

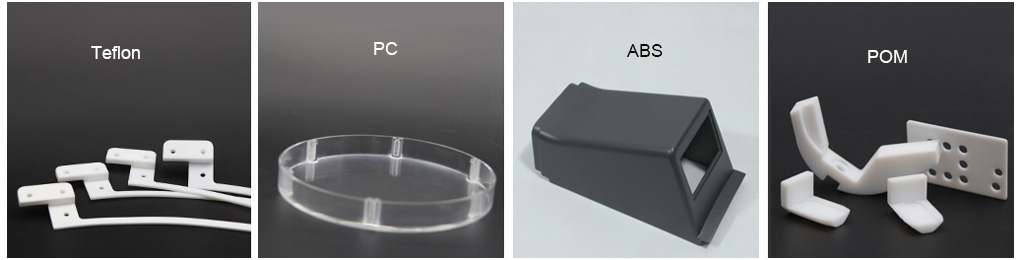

1. ABS: It is widely used in general product casings and has good dissolving strength. It can be applied to surface finish, such as water plating and vacuum evaporation plating. The material specifications include plates and round bars. ABS is divided into general grade and fireproof grade, which is basically consistent with the performance of injection molding plastics, so that’s why it become the most widely used in the rapid prototyping industry.

2, PC: strength, toughness, transparency, all performance is excellent, it suitable for Lens, precise structure parts. In addition, glass fiber is added to improve the rigidity and heat resistance of the sheet, which can be used to produce parts requiring high rigidity in a high temperature environment. PC also has UL94-V0 fire rating.

3, PMMA: Acrylic, or plexiglass. It is a good transparent piece, and the material is best for the transparency parts and it can be applied by dyeing, electroplating, spraying, screen printing and other processes. The dissolving strength is acceptable, only its weakness is brittle and fragile, and it is not suitable for use in fragile parts such as hooks.

4, PP: translucent material, good impact resistance, excellent flexibility, it can be applied to the production requirements of strict impact resistance, such as: automotive supplies, folding boxes.

5, PA66 + GF30: PA66 + GF30 is not a model, it is the general name for the PA66 plastic raw materials plus 30% glass fiber. With high strength, special heat stability, hydrolysis resistance, suitable for automotive parts, mechanical parts. For mechanical parts shields that require high rigidity and dimensional stability. Red phosphorus flame retardant has long-term stability and excellent mechanical properties.

6. POM: it is called polymethyl hydrazine raw material, also known as polyoxymethylene methine raw material. Its molecular structure and crystallinity make it excellent in physical and mechanical properties. It is called metal plastic. In the rapid prototyping industry, it is suitable for workpieces with high strength, such as: gears, shafts, brackets, etc.

7, Teflon: chemical name polytetrafluoroethylene (Poly tetra fluoroethylene, abbreviated as PTFE), commonly referred to as “non-stick coating” or “easy to clean materials.” This material has the characteristics of acid and alkali resistance and resistance to all kinds of organic solvents, almost insoluble in all solvents, also PTFE has the characteristics of high temperature resistance, its friction coefficient is extremely low, so it can be used as a lubrication, and it is also an ideal material for easy cleaning of the inner layer of water pipes.

8. Aluminum alloy: Aluminum alloy is the most widely used metal structural material in the rapid prototyping industry. It has been widely used in aviation, aerospace, automotive, medical and marine prototypes. At present, the Aluminum alloy has the most application in the rapid prototyping industry, its advantages are easy processing, good rigidity and rich color for anodizing.

9. Brass: Brass is an alloy composed of copper and zinc. Brass composed of copper and zinc is called ordinary brass. If it is a mixture of two or more elements, it is called special yellow copper. Brass has strong wear resistance. Brass is often used in prototyping to replace materials such as stainless steel, which are difficult to engrave and mill. After polishing and plating, the surface effect and feel are very close to stainless steel.

10. Stainless steel: It is more and more popular because of its beautiful appearance, corrosion resistance and non-damage. Iron and steel are distinguished by the amount of carbon. An iron-carbon alloy having a carbon content of 2% or less is steel, and a carbon content of 2% or more is called iron. Steel is widely used because of its toughness, elasticity and rigidity.

CNC machining can be done with different materials than used in the 3D printing process, our CNC machining is compatible with a wide range of materials, from plastic to metal, working with multiple grades of steel, stainless steel and aluminum, as well as copper and brass, plastic material include ABS, POM, Acrylic, PC, PMMA and more on.

With so many material options available, machined products can meet just about most mechanical requirements your project may have.